Then Production

Dynamic and advanced planning and scheduling

Revolutionary planning engine

Then Production runs a unique production planning engine that will adapt itself to you and your companies needs dynamically, as new requirements and constraints arise.

Is your production based on make-to-order, make-to-stock or a combinations of this, Then Production will handle it, whether you want a finite schedule or infinite schedule, if you prefer Just-In-Time production or similar, Then Production adapts dynamically to your supply chain.

What is unique?

Then Production carefully assets the uncertainty in your forecast or the frequency of your orders to give you the safest plan and sequence of products to produce. The system calculates and sees billions of possible plans and chooses the one that best fits your needs.

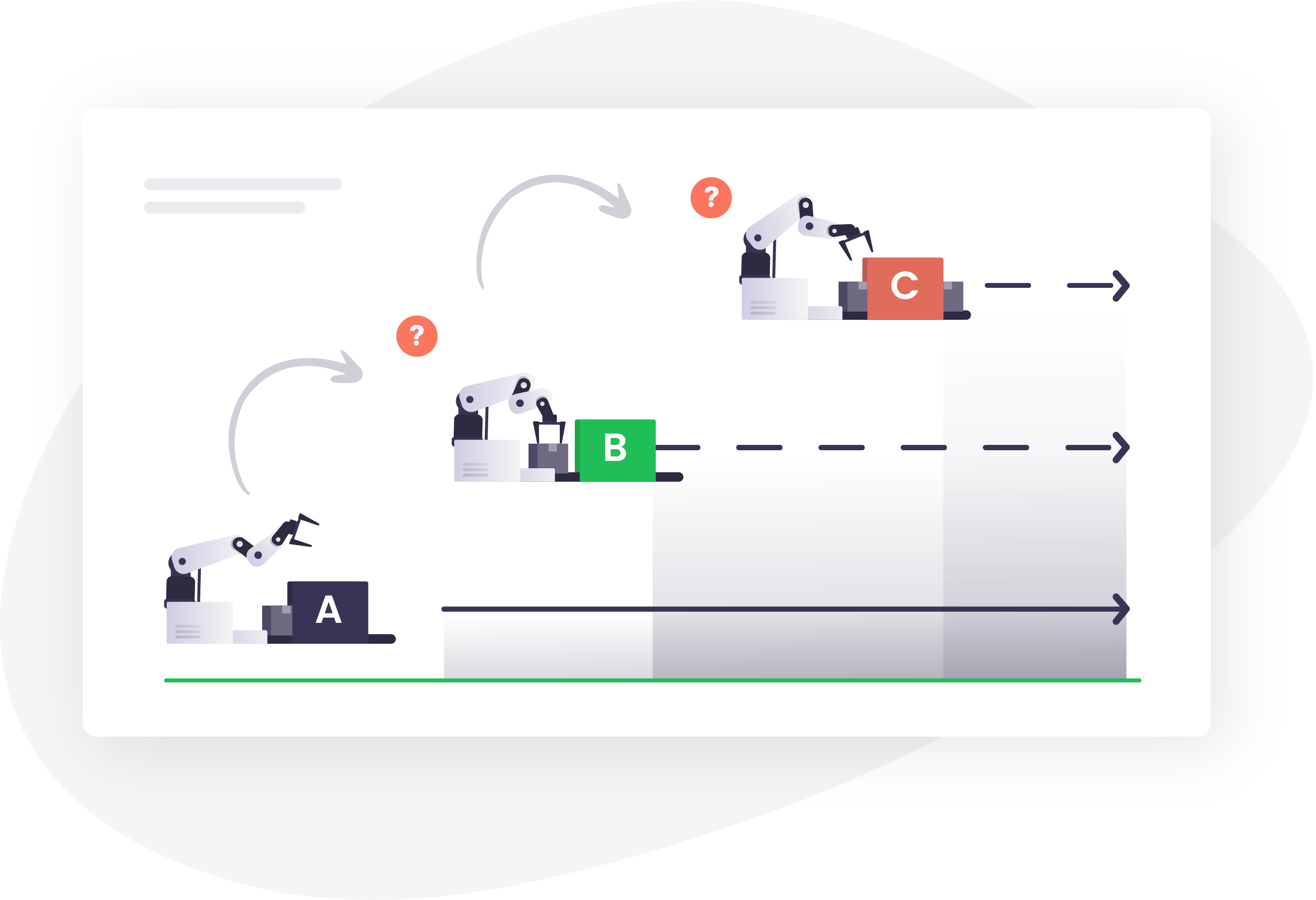

You can be certain that Then Production will produce the best master production schedule according to your available capacity, where it will reduce locked planning horizons and dynamically reschedule productions jobs during unforeseen production situations or arrival of new and prioritized customer orders.

The Planning

Then Production handles planning on different horizons and periods, and accepts forecast, orders, capacity information and various other constraints in your supply chain. With this the system can generate accurate material and capacity requirements, either you plan for days, weeks, months, years or any combination of this.

Revolutionary and proprietary algorithms calculate your requirements and are configured to accept real time production status and recalculate new requirements as they are detected. The system is also user friendly and allow simple drag and drop functionality to immediately change parts of the master production schedule or similar.

Sequencing

The cutting edge sequencing engine in Then Production can adapt to various productions, lines and machines, and create optimal sequences of products to produce.

Together we define your constraints like available resources, operator matrices, machine capacities, product changeover times, batches, overtime and any other constraints deemed necessary for the engine to use, and at the same time have the ability to add more later.

Changes to various sequences on the shop-floor automatically escalate up to the master production schedule if conflicts arise, and production planners will have full control to either let the system decide best outputs, or add new constraints or prioritized orders from unexpected changes.

Powerful What-If analysis

Then Production lets you easily simulate different scenarios on your production plans and production sequences.

Are you lacking the right amount of raw materials, operators staying home because of sickness, machines breaking down or similar, the system is capable of simulating various scenarios.

The best part of the scenario analysis is that the system does not only show you what can happen to your production, but also what can happen for the rest of your supply chain. This is equally true the other way around if you use what-if analysis from Then Forecasting module.

Easy integration

Then Production can easily be integrated into your ERP or Financial system, or just read your Excel sheets to import Bill of Materials, demand forecasts, orders and much more. At the same time the system can be setup to send back planned production to your ERP system or similar.

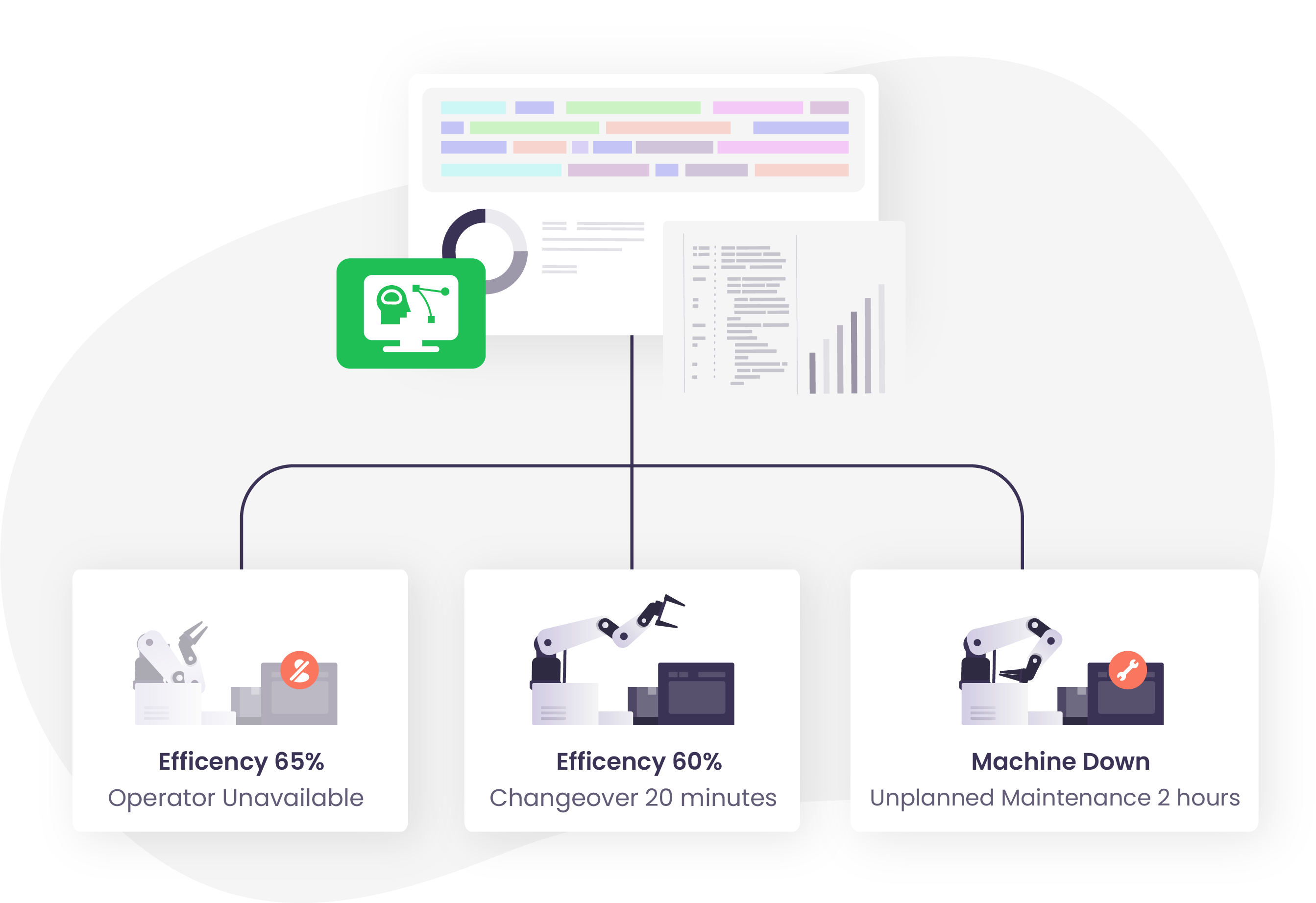

It can also receive raw information from your machines like efficiency from your factory systems, Excel sheets or database system, in order to plan better.

Then Production adapts to your firm and solve the problems you have today and tomorrow, no matter if you are a small company with no systems at all, or a big company with a complex ERP system. Lets have a talk on how Future Then can automate and digitize your planning.