Visual reading of analogue equipment

Visual reading of analogue equipment

STATE-OF-THE-ART-SOLUTIONS

We provide solutions based on the latest technology to ensure optimal performance for all challenges.

EXPERTISE AND COMPETENCE

Our experts in industrial machine vision and artificial intelligence ensure the best solutions for your challenges.

TAILORED SYSTEMS

Our advanced machine vision and AI expertise, combined with our selected product portfolio, provides you with the best machine vision solution.

MACHINE VISION SOLUTIONS FROM ONE PLACE

With us, you get the entire project from one source. Products, development, services, training, and much more. We know what it takes to solve any machine vision problem.

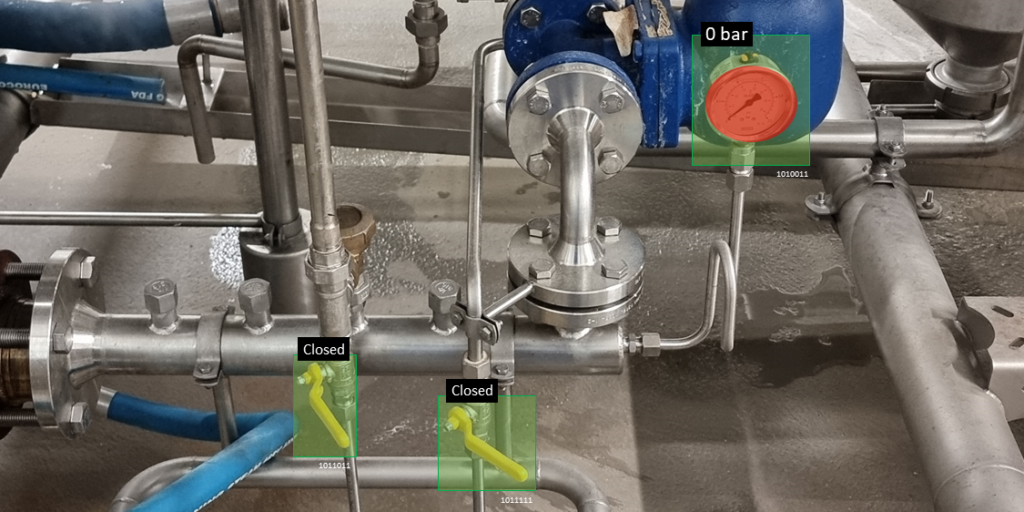

Explore the possibilities of inspecting analog equipment

Explore our innovative machine vision solution for visual reading of analog equipment, offering significant benefits in automation, accuracy, and efficiency in production processes.

Machine vision control of analog equipment

Analog equipment such as gauges, dials, and other instruments that display values through needles, indicators, or LED lights can be monitored and read using machine vision technology. For analog equipment like pressure gauges, thermometers, voltmeters, flow meters, and other instruments that present data in an analog format, the specific values to be read and how these values should be used in the production or monitoring process will be defined.

Advantages of using machine vision for reading

For various businesses, there are several advantages to these advanced solutions. Machine vision technology can, first and foremost, read analog gauges with high precision, eliminating human reading errors. Automated and continuous monitoring and real-time reading improve response times and free up employees to focus on other essential tasks. Machine vision systems provide flexibility by functioning with a wide range of analog instruments and can be used to control process parameters through direct contact with PLCs or similar systems. Regardless of your needs, our solutions can be integrated to help you achieve your goals

System Integration and Notification

Seamless integration with ERP, MES, and SCADA systems provides a comprehensive overview of the production process and enhances decision-making. Real-time data transfer can be achieved by implementing systems that enable data exchange between the machine vision system and ERP, MES, or SCADA systems. API integration can be used to facilitate the data exchange between machine vision sensors and the existing maintenance systems.

For communication with other process equipment, such as PLCs, anything from simple IO signals to modern Ethernet-based industrial protocols can be used. This allows vision sensors and PLCs to work together for process notification or parameter adjustments. For example, emergency shutdowns of process equipment can be triggered if camera sensors detect issues such as leaks or elevated temperatures that simpler sensors cannot detect.

Take control of your maintenance and harness the benefits!

Don’t wait for problems to arise. With our Machine Vision solutions, you can take control of maintenance and ensure that analog equipment always displays the necessary information for decision-making. Businesses will no longer have to worry about inaccurate or unreliable readings. With our expertise in artificial intelligence and machine vision technology, you’ll always be one step ahead, allowing your business to achieve efficient workload distribution, time savings, and reduced costs.

Take quality control to the next level

Our machine vision sensors can assist you with automatic and flawless quality control of production and machinery. With our technology, you can reduce errors, improve efficiency, and increase profitability. Contact us today to learn more about how our solutions can help your business.

Contact us today

Let us help you navigate this exciting technology. Contact us today to discuss how we can assist you in implementing machine vision sensors in your process. We look forward to hearing from you!