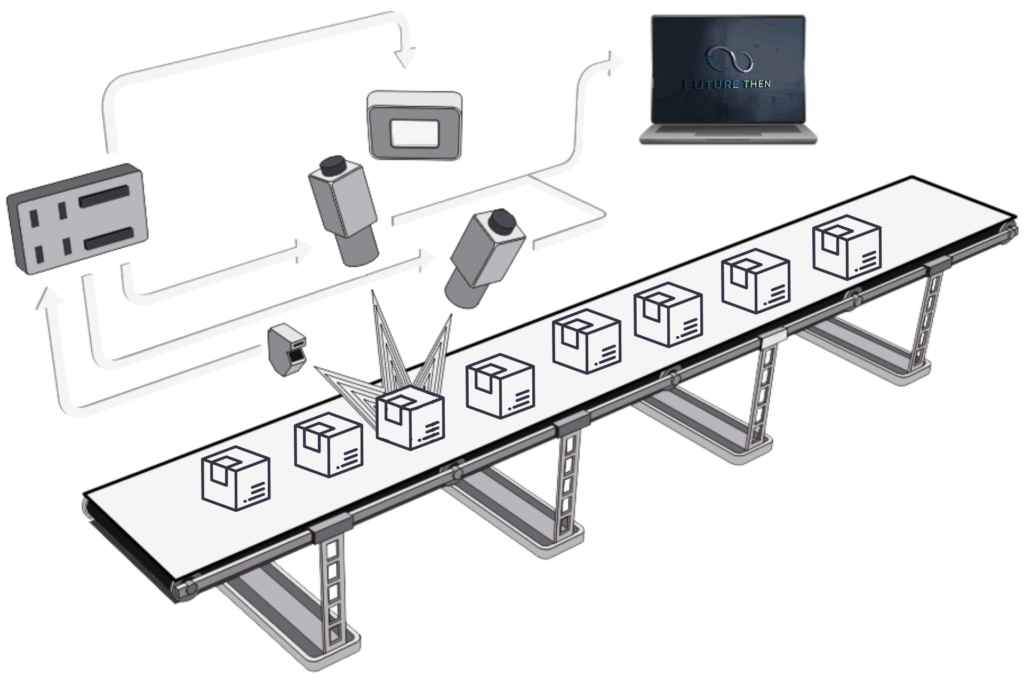

Traceability and control of goods between camera and ERP

Traceability and control of goods between the camera and ERP/MES system

STATE-OF-THE-ART-SOLUTIONS

We provide solutions based on the latest technology to ensure optimal performance for all challenges.

EXPERTISE AND COMPETENCE

Our experts in industrial machine vision and artificial intelligence ensure the best solutions for your challenges.

TAILORED SYSTEMS

Our advanced machine vision and AI expertise, combined with our selected product portfolio, provides you with the best machine vision solution.

MACHINE VISION SOLUTIONS FROM ONE PLACE

With us, you get the entire project from one source. Products, development, services, training, and much more. We know what it takes to solve any machine vision problem.

A simple integration into the company’s production protocols

The integration of machine vision systems with ERP/MES systems provides significant benefits for traceability, quality control, and efficiency in production processes. Proper implementation and management of challenges ensure that businesses can achieve higher standards of product quality and operational efficiency.

Integration with Future Then Vision

Future Then Vision is our own machine vision solution that can be used to control and manage inspections with one or more of our cameras and other sensors. It can also be integrated with your ERP, MES, or SCADA system for sending and receiving data to and from production.

Integration with ERP/MES Systems

Inspection results captured by vision sensors can be transferred in real-time to ERP/MES systems for further processing and analysis. The ERP/MES systems will receive data on each individual unit, including inspection details, production status, and any discrepancies. Based on the inspection data, the ERP/MES systems can automatically take actions such as stopping the production line or notifying operators.

Traceability

All production details, inspection results, and any corrective actions stored in the ERP/MES system enable full traceability and audit trails, which are necessary for compliance with regulatory requirements and internal quality standards. This way, products can be traced back to specific batches or production runs, facilitating batch control and any recall processes.

Benefits

The integration between machine vision systems and ERP/MES systems enables real-time data exchange and provides a comprehensive overview of the production line. A consolidated view of production and quality data will offer a better decision-making foundation for the business, providing better control and the ability to respond quickly to issues..

Take quality control to the next level

Our machine vision sensors can assist you with automatic and flawless quality control of production and machinery. With our technology, you can reduce errors, improve efficiency, and increase profitability. Contact us today to learn more about how our solutions can help your business.

Contact us today

Let us help you navigate this exciting technology. Contact us today to discuss how we can assist you in implementing machine vision sensors into your process. We look forward to hearing from you!