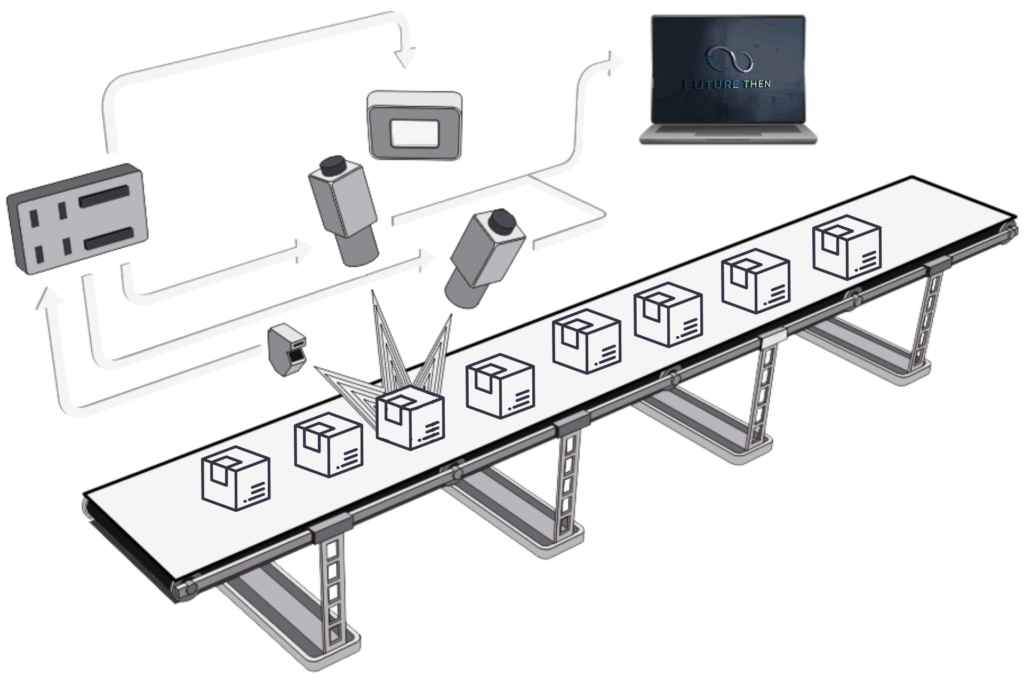

Discover boxes with errors

Discover boxes that are deformed, misassembled, or have other defects

STATE-OF-THE-ART-SOLUTIONS

We provide solutions based on the latest technology to ensure optimal performance for all challenges.

EXPERTISE AND COMPETENCE

Our experts in industrial machine vision and artificial intelligence ensure the best solutions for your challenges.

TAILORED SYSTEMS

Our advanced machine vision and AI expertise, combined with our selected product portfolio, provides you with the best machine vision solution.

MACHINE VISION SOLUTIONS FROM ONE PLACE

With us, you get the entire project from one source. Products, development, services, training, and much more. We know what it takes to solve any machine vision problem.

Ensure quality control with machine vision

Using vision systems, it is possible to automatically quality-check boxes for proper sealing, various damages, or defects at all levels and environments within industrial plants or warehouses. Defects such as deformations, misassembled areas, and other physical damages to boxes can be easily detected and corrected. Machine vision solutions are designed to ensure that the quality inspection of boxes runs smoothly and problem-free for all types of businesses, manufacturers, and suppliers handling packaging. In this way, lost production time, waste, and dissatisfied customers due to issues with product packaging can be avoided.

Precise detection of defects

Using advanced image processing algorithms, camera sensors can identify and detect small defects on all types of boxes. Any minor defects that may be difficult to see with the naked eye and that could cause issues for packaging and the products inside will be easily recognized and controlled by machine vision.

Enhanced and increased productivity

By automating quality control of boxes and similar packaging and ensuring that all quality requirements are met before finished goods are shipped, a significant amount of time can be freed up for the business. A considerable portion of the workload can be reduced for employees, and more time to focus on other demanding tasks will contribute to increased efficiency and productivity.

Reduction of waste

By quality-checking boxes as early as possible in the production process, the amount of waste can be significantly reduced. This is not only good for the environment but can also lead to substantial cost savings. Additionally, it can enhance the company’s sustainability profile, which is attractive to environmentally conscious customers. By minimizing waste, businesses can also meet environmental standards and regulations, which are crucial for maintaining necessary certifications and permits.

Customer satisfaction

By having flawless inspection of boxes, this can increase customer satisfaction. Flawless quality of boxes and other packaging will help build stronger customer relationships and loyalty. Over time, this can improve the company’s reputation and increase market share. By ensuring the correct quality of packaged goods with machine vision, businesses can avoid unnecessary complaints and reviews, which would otherwise negatively impact the company’s reputation.

Take quality control to the next level

Our machine vision sensors can assist you with automatic and flawless quality control of production and machinery. With our technology, you can reduce errors, improve efficiency, and increase profitability. Contact us today to learn more about how our solutions can benefit your business.

Contact us today

Let us help you navigate this exciting technology. Contact us today to discuss how we can assist you in implementing machine vision sensors into your process. We look forward to hearing from you!