Detect wear with micrometer precision

Detect wear with micrometer precision

STATE-OF-THE-ART-SOLUTIONS

We provide solutions based on the latest technology to ensure optimal performance for all challenges.

EXPERTISE AND COMPETENCE

Our experts in industrial machine vision and artificial intelligence ensure the best solutions for your challenges.

TAILORED SYSTEMS

Our advanced machine vision and AI expertise, combined with our selected product portfolio, provides you with the best machine vision solution.

MACHINE VISION SOLUTIONS FROM ONE PLACE

With us, you get the entire project from one source. Products, development, services, training, and much more. We know what it takes to solve any machine vision problem.

Discover wear with precision detection

Our groundbreaking technology provides cost-effective preventive maintenance and allows you to detect wear with micrometer precision, enabling you to plan and take action before it becomes problematic.

Machine Vision and Micrometer Precision

Our machine vision systems are capable of achieving micrometer precision. This allows for the detection of changes smaller than a thousandth of a millimeter. In this way, vision technology can identify signs of wear long before they become visible to the naked eye. By utilizing 3D technology, it is possible to create 3D models of the surfaces to be inspected, providing a more detailed analysis of wear. With techniques such as laser scanning, surface structure can be measured with high precision. AI systems can automatically classify the type and severity of wear, while training machine learning models with large datasets that include images of both intact and worn surfaces can enhance detection accuracy.

Benefits of this technology

Early detection of wear offers many benefits for businesses. Firstly, it can prevent costly repairs and unexpected downtime. By detecting and addressing wear issues early, a significant amount of resources and time can be saved. Early detection of wear also prevents the production of defective products, reducing material waste. Secondly, data-driven maintenance based on actual equipment condition reduces unnecessary maintenance activities and extends the lifespan of equipment. Thirdly, automated inspection reduces the risk of human error during visual inspections, ensuring that wear is detected and corrected at the right time.

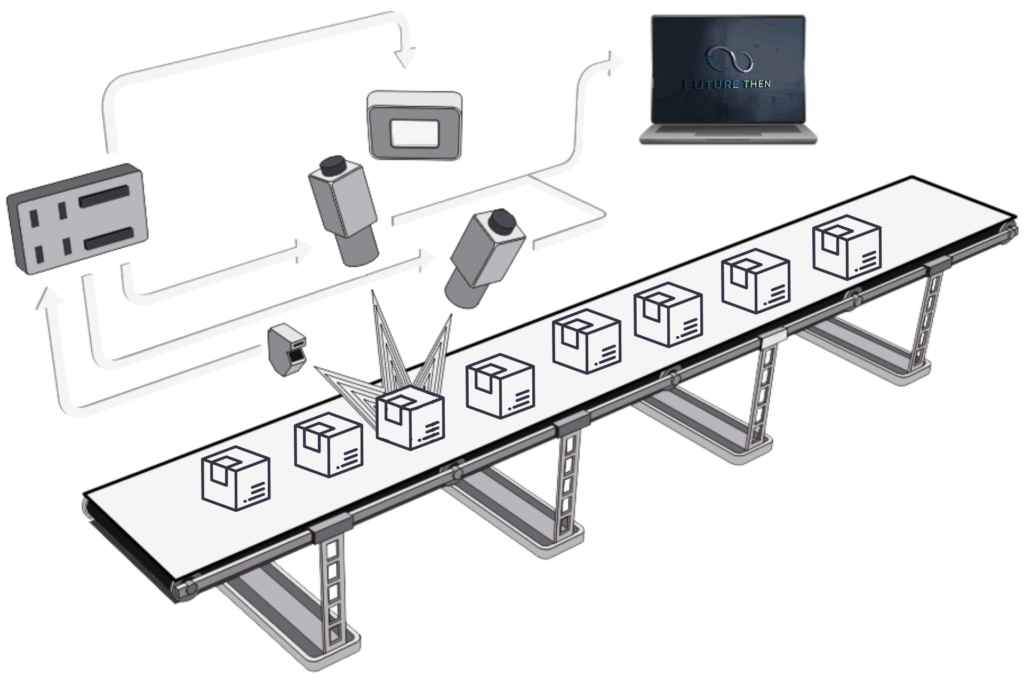

System Integration and Monitoring

Integrating machine vision solutions into production lines for wear inspection ensures that inspection data is effectively utilized in maintenance systems and production management. Real-time data transmission can occur by implementing systems to transfer data from the machine vision system to ERP, MES, or SCADA systems. API integration can be used to ensure seamless data exchange between machine vision sensors and existing maintenance systems.

Furthermore, as described above, a simple integration can be incorporated with automated maintenance alerts and monitoring. Notification systems will inform maintenance personnel when the system detects wear on machinery or materials, while monitoring can be carried out through monitoring dashboards, providing real-time insights into the efficiency of the maintenance process and the condition of various locations and machines experiencing wear.

Take control of your maintenance and leverage the benefits!

Don’t wait for problems to arise. With our Machine Vision solutions, you can take control of your maintenance and ensure that machines and equipment are always in top condition. With vision systems, you can plan maintenance when it suits you, and avoid unexpected downtimes due to unforeseen wear or other similar challenges. With our expertise in artificial intelligence and machine vision technology, you’ll always be one step ahead, enabling your business to achieve efficient task allocation, time management, and reduced costs.

Take quality control to the next level

Our machine vision sensors can assist you with automatic and flawless quality control of production and machinery. With our technology, you can reduce errors, improve efficiency, and increase profitability. Contact us today to learn more about how our solutions can benefit your business.

Contact us today

Let us help you navigate this exciting technology. Contact us today to discuss how we can assist you in implementing machine vision sensors into your process. We look forward to hearing from you!