Check that the date and lot number are correct

Check that the date and batch number are readable and correct at high speed

STATE-OF-THE-ART-SOLUTIONS

We provide solutions based on the latest technology to ensure optimal performance for all challenges.

EXPERTISE AND COMPETENCE

Our experts in industrial machine vision and artificial intelligence ensure the best solutions for your challenges.

TAILORED SYSTEMS

Our advanced machine vision and AI expertise, combined with our selected product portfolio, provides you with the best machine vision solution.

MACHINE VISION SOLUTIONS FROM ONE PLACE

With us, you get the entire project from one source. Products, development, services, training, and much more. We know what it takes to solve any machine vision problem.

Ensure traceability with high-speed machine vision

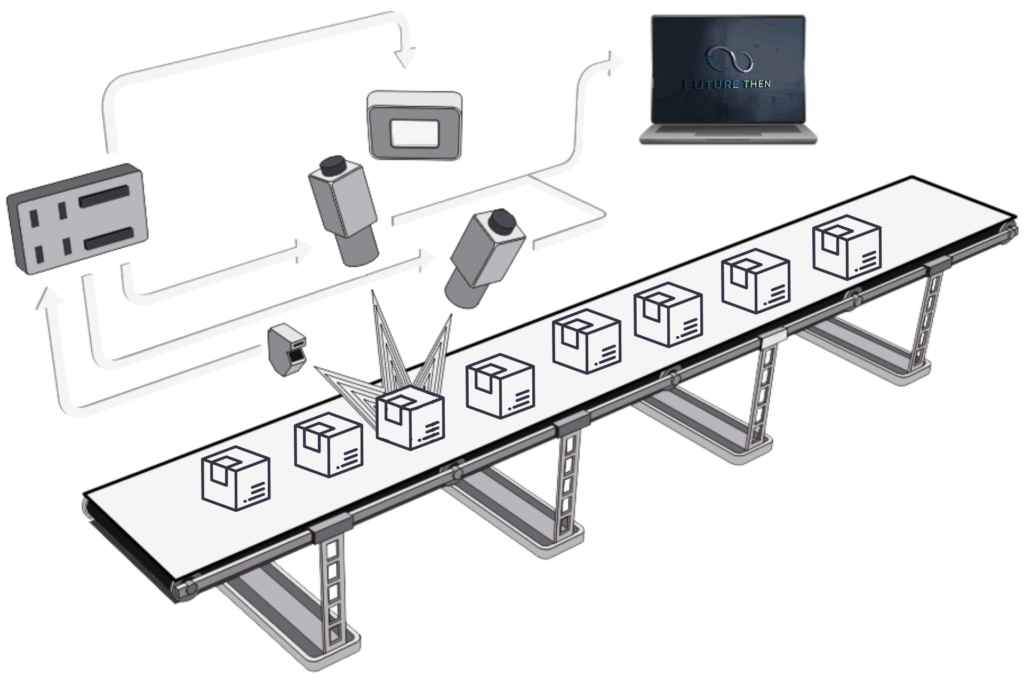

Labeling quality inspection can be automated and enhanced using machine vision systems. Everything from the date to the barcode and batch number can be identified and quality assured with camera systems at a revolutionary high speed, ensuring the business that each product is correctly labeled and ready for distribution.

Solid accuracy at high speed

By utilizing vision systems for labeling quality inspection, industries can achieve automatic quality checks with the highest possible accuracy. Vision sensors, operating at very high speeds, will ensure that labels contain correct text, barcodes, graphics, and logos, and that the labels are properly aligned and placed on the product. Machine vision solutions can continuously perform inspections at such production speeds for higher efficiency, without creating bottlenecks. This will help ensure regulatory compliance, reduce costs and time associated with errors, and provide valuable data for continuous improvement.

Fast data capture

With machine vision, date and batch numbers can be read and verified at incredible speeds. This means that even on a high-speed production line, each product can be checked without slowing down production. This enables businesses to increase production speed without sacrificing quality control, leading to higher productivity and profitability.

Integrated solution

Machine vision solutions integrate seamlessly with other production controls and systems. Businesses can customize vision solutions to best suit their needs without creating any disadvantages or significant costs. With simple turn-key solutions, minimal training, and adjustments, companies can start benefiting immediately. From screen-based solutions to centralized systems where a camera sensor can simultaneously check text, codes, and more, everything is possible based on how the company wants the inspection process to work. Through proper implementation, businesses can achieve significant improvements in product quality, production speed, and cost savings.

Benefits of improved and automated traceability

Consistent and accurate label inspection ensures that only products meeting quality standards are forwarded. This helps reduce costly recalls, waste, and ensures customer satisfaction. These machine vision solutions will also eliminate the need for manual inspection, reducing the risk of human error, and freeing up labor.

Take quality control to the next level

Our machine vision sensors can assist you with automatic and flawless quality control of production and machinery. With our technology, you can reduce errors, improve efficiency, and increase profitability. Contact us today to learn more about how our solutions can help your business.

Contact us today

Let us help you navigate this exciting technology. Contact us today to discuss how we can assist you in implementing machine vision sensors in your process. We look forward to hearing from you!