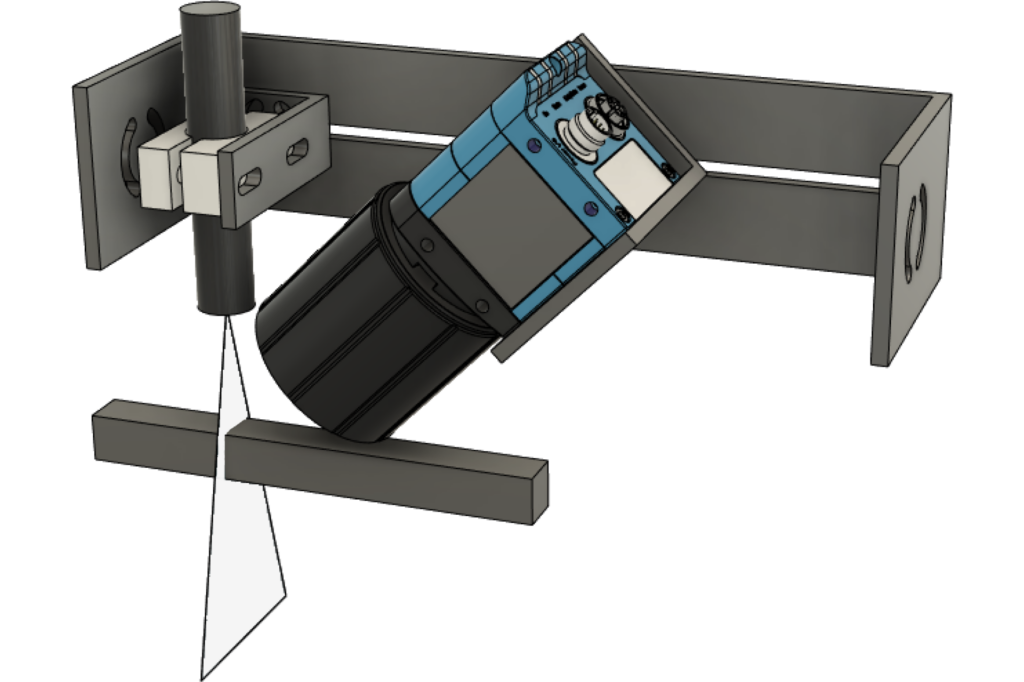

Check sealing with precise 3D inspection

Inspection of the sealing of bags, bowls, and other finished product packaging.

STATE-OF-THE-ART-SOLUTIONS

We provide solutions based on the latest technology to ensure optimal performance for all challenges.

EXPERTISE AND COMPETENCE

Our experts in industrial machine vision and artificial intelligence ensure the best solutions for your challenges.

TAILORED SYSTEMS

Our advanced machine vision and AI expertise, combined with our selected product portfolio, provides you with the best machine vision solution.

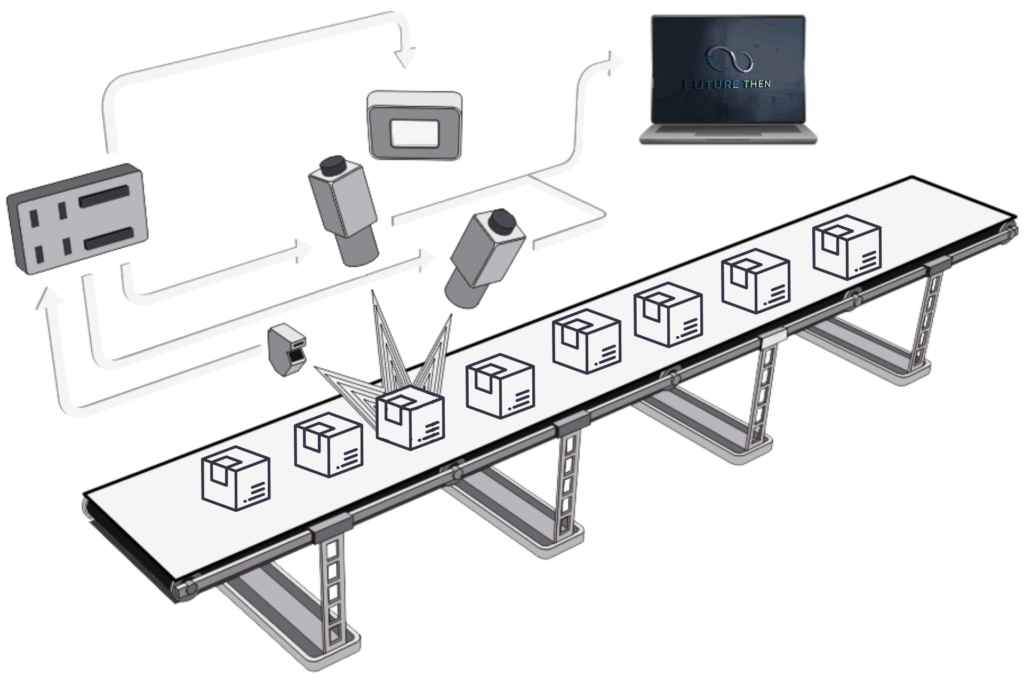

MACHINE VISION SOLUTIONS FROM ONE PLACE

With us, you get the entire project from one source. Products, development, services, training, and much more. We know what it takes to solve any machine vision problem.

Explore the power of vision systems for seal inspection

An advanced solution using machine vision will ensure that different products are sealed correctly according to production specifications, thereby maintaining high quality and reducing error margins.

Quality assurance of seals using machine vision technology

Packaging that is improperly sealed or has other damages and defects that could lead to production stoppages or costly recalls can be immediately identified and corrected to prevent such setbacks and ensure flawless inspection. Using machine learning and advanced algorithms, automatic and error-free inspection is achievable for all types of packaging, ensuring production specifications are met. Color, shape, appearance, and size are irrelevant. Everything that humans can see, machine vision can also detect, without fatigue or exhaustion. Any sealing defects can be identified and corrected immediately, reducing the need for manual inspection and rework. This not only leads to cost savings but also contributes to a more sustainable production process.

Accurate and reliable

Vision systems provide a detailed and accurate analysis of the seal. Machine vision technology enables real-time detection of irregularities in the sealing process, ensuring that all products are properly sealed before reaching the consumer. This technology can identify and inspect even the smallest defects that may be invisible to the naked eye. By utilizing various types of machine vision technology, no faults will go unnoticed, and products will always be correctly sealed according to the company’s standards.

Fast and efficient

With machine vision solutions, the sealing of hundreds of products can be inspected per minute. This makes the process fast and efficient, allowing businesses to save time and resources.

Improves product quality

By ensuring that the seal is always perfect, this solution helps businesses improve the quality of their products. Furthermore, this technology can assist companies in complying with strict quality standards and regulations, which is essential for maintaining certifications and customer trust. Machine vision systems can easily be integrated into existing production lines, making them a flexible and efficient solution for ensuring high quality in finished product packaging.

Take quality control to the next level

Our machine vision sensors can assist you with automatic and flawless quality control of production and machinery. With our technology, you can reduce errors, improve efficiency, and increase profitability. Contact us today to learn more about how our solutions can help your business.

Contact us today

Let us help you navigate this exciting technology. Contact us today to discuss how we can assist you in implementing machine vision sensors in your process. We look forward to hearing from you!