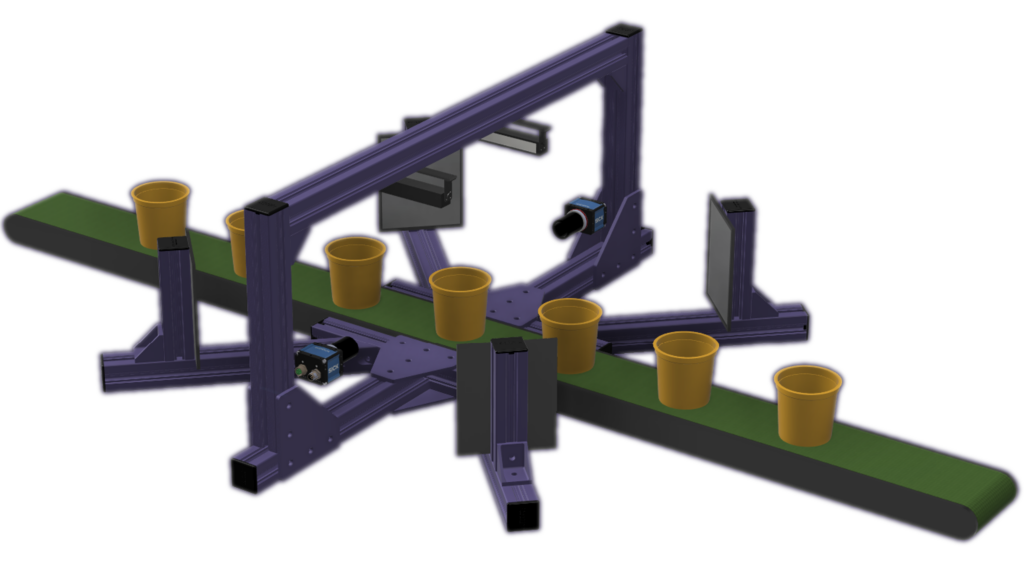

AI-powered checking of cups

AI-driven inspection of cups, cans, and bottles

STATE-OF-THE-ART-SOLUTIONS

We provide solutions based on the latest technology to ensure optimal performance for all challenges.

EXPERTISE AND COMPETENCE

Our experts in industrial machine vision and artificial intelligence ensure the best solutions for your challenges.

TAILORED SYSTEMS

Our advanced machine vision and AI expertise, combined with our selected product portfolio, provides you with the best machine vision solution.

MACHINE VISION SOLUTIONS FROM ONE PLACE

With us, you get the entire project from one source. Products, development, services, training, and much more. We know what it takes to solve any machine vision problem.

Ensure accuracy with AI-driven inspection

An advanced machine vision solution for AI-driven inspection of shape and labels on cups, cans, and bottles ensures a high level of automation, accuracy, and efficiency in the inspection process.

Precise inspection and automatic quality control at high speed

Our inspection solution automatically checks for a range of common issues with cups, cans, and bottles. Supporting speeds of up to 450 units per minute, inspections are performed accurately even at high speeds, with faulty products automatically removed from the production line.

Using advanced algorithms, it verifies that labels are properly positioned, securely attached, contain the correct text, and that the right label is used for the product. At the same time, AI algorithms ensure that defects such as damage, spills on the can, and cracks in the cup are reliably detected.

Automated setup of new products

Traditional systems often require a long time to configure the solution for new products, which can be time-consuming and costly. With our AI-driven machine vision, the system can be quickly and easily trained to adapt to new product variants. This reduces configuration time to a fraction of what is required with traditional methods.

Easy integration

The solution is designed to ensure easy integration with the company’s existing production systems. With broad support for industrial protocols, data exchange can occur in real-time between the machine vision system and PLC, ERP, MES, or SCADA systems.

Robust integration ensures that the solution always has up-to-date product and production data, and that other systems are kept updated in real-time to ensure full traceability and documentation that all products meet quality standards.

Discover the cause of errors

The ability for extensive data collection and reporting enables understanding of when errors occur and helps identify correlations with other activities on the factory floor.

Take quality control to the next level

Our machine vision sensors can assist you with automatic and precise quality control of production and machinery. With our technology, you can reduce errors, improve efficiency, and increase profitability.

Contact us today

Let us help you implement this exciting technology. Contact us today to discuss how we can integrate machine vision sensors into your production process. We look forward to hearing from you!